This is the second in a series of blog posts based on the applied research report, “Advanced Supply Chain Planning: Leading Edge Capabilities Needed to Win in 2030,” by the research team of Michael Burnette, Dan Pellathy, Karen Mathews, and Daniel Myers. Download the white paper. Read the first post, “Why Supply Chain Planning is More Critical Than Ever Before.”

Supply chain planning is a process that coordinates assets, resources, and information to maximize customer and organizational value creation. It involves everything from coordinating supply chain activities and transitions to delivering optimal customer service, inventory, and cost levels. Planning excellence requires skills, training, and a knowledge of work processes, scorecards, and culture.

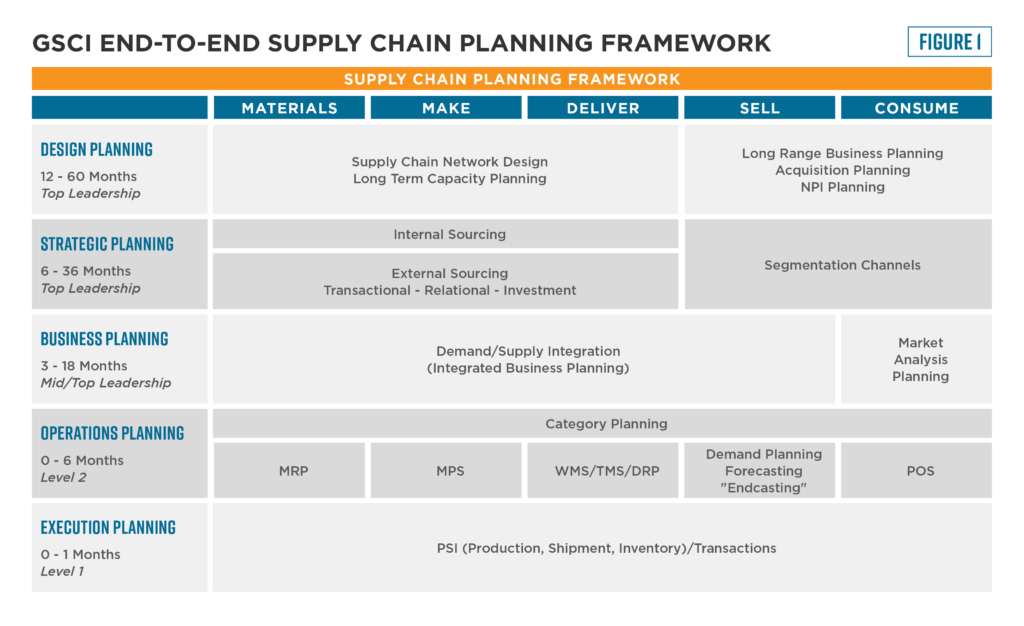

The figure below shows the GSCI End-to-End Supply Chain Planning Framework, which illustrates the five types of planning required in today’s complex global supply systems. To manage an E2E system, planners must draw on internal and external resources distributed across procurement, manufacturing, engineering, process control, quality, safety, innovation program management, warehousing, transportation, and logistics.

Put simply, a planner’s job is to ensure that resources are continuously realigned to maximize value creation.

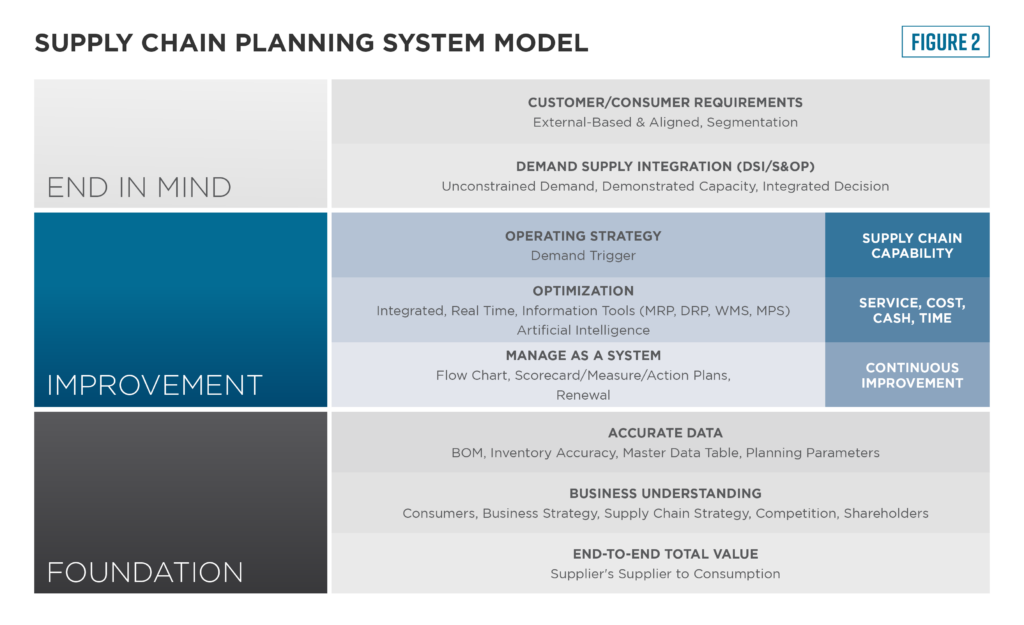

Supply chain managers must keep at least three essential principles in mind as they build a robust planning system.

- Planning processes are intended to optimize total value by meeting or exceeding consumer and customer requirements. Successful planning systems keep this end in mind. Keeping them at the top of the planning process model is a reminder that, no matter how efficient, the process is only effective if it delivers total value.

- Planning processes must focus on continuous improvement. Supply chains today are highly complex. Managers must continuously renew their planning systems, leveraging new tools to improve decision-making. In addition, planners must align decisions with supply chain operating strategies that deliver competitive cost and service and effectively use cash.

- Planning must be built on a foundation of end-to-end value, business understanding, and data accuracy. To optimize end-to-end value, planners must take a holistic approach to decision-making. At the same time, they must have a deep understanding of the business, strategy, competitive strengths and weaknesses, shareholder needs, and the end-to-end supply chain process. Without this strong foundation, the system will remain unstable.

As companies work to develop best practices in their planning systems, they will inevitably require some guidance. In an earlier report, we outlined Nine Supply Chain Planning Maxims that serve as core principles around which companies can develop their planning capabilities.

A detailed description of each is available in the downloadable report. In their simplest form, the maxims are as follows:

- End-to-end supply chain planning begins with a deep understanding of business and supply chain strategy

- Plans are based on an end-to-end, integrated supply chain

- Let the systems do the work

- Data accuracy is the job number one

- Variation creates waste

- Competitive advantage is built not from inventory but superior supply chain capability

- Under every pile of inventory is a supply chain defect

- Segment and prioritize transactions at all levels of the planning framework to drive effectiveness and efficiency

- Time matters

As the business environment evolves, the importance of supply chain planning grows. Thousands of activities, executed across increasingly complex networks, create the potential for failures, both large and small. Excess waste and cost to non-value-added inventory and diminished customer service can significantly impact success. Benchmark supply chains are fast at work, building robust planning systems that incorporate the maxims listed above.

At the same time, leaders must recognize that planning excellence is a moving target. Companies need to build a solid foundation for today while investing in the capabilities required for success tomorrow.

Our third and final post in this series will be the most extensive, detailing the Seven Leading-Edge Capabilities our team developed based on in-depth interviews with over a dozen leaders across nearly 20 industries. Implementing these capabilities will ensure your organization succeeds beyond 2030.

To learn more about how your company can partner with us to explore advanced concepts in supply chain management, visit ASCC.

Download the white paper by filling out the form below to read more about meeting the challenge of supply chain agility.