Companies may soon be required to measure and report greenhouse gas emissions across their supply chains. The first article in this two-part series examines current standards for measuring truck emissions. In the second article, Alex Scott, a transportation researcher with more than two decades in the trucking industry, recommends a science-based, data-driven method he’s developed for improving how scope 3 truck emissions are measured.

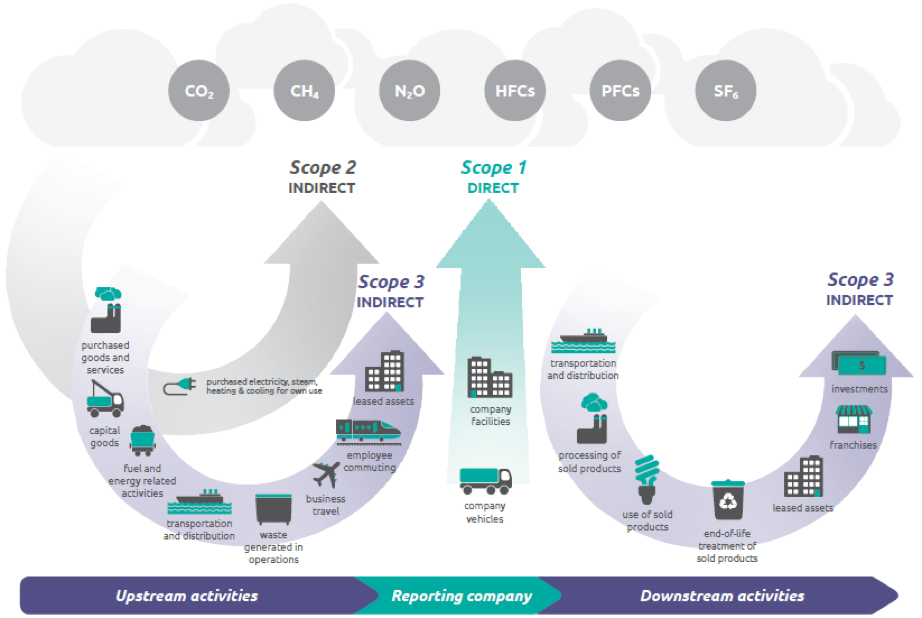

Regulators in the United States and Europe have increasingly focused their attention on scope 3 emissions, which are defined as those that result from “assets not owned or controlled by the reporting organization, but that the organization indirectly affects in its value chain.” Rules or legislation currently under consideration by the Securities and Exchange Commission (SEC), the European Union, and the state of California may soon require companies to periodically measure and report their scope 3 greenhouse gas (GHG) emissions, which would include emissions from trucks.

Measuring scope 3 GHG emissions can be difficult. For example, aggregating emissions for complex products, such as cars, with many components and suppliers presents challenges, especially when each supplier, in turn, serves multiple customers. Because of these complexities, there are few agreed-upon, universal standards for measuring scope 3 emissions. Any widely acceptable standards that do exist are likely to be context-specific. Truck transportation, which is one of the largest sources of scope 3 emissions, is a relatively standardized service where universal principles can and should be established to make reporting requirements efficient, comparable, and transparent.

Background on Scope 3 Emissions

GHG emissions are often categorized into three distinct types, or scopes, of emissions. From the focal point of a specific company, scope 1 emissions are direct emissions, or those that emanate directly from assets owned by the company (e.g., a manufacturing plant or truck). Scope 2 emissions are those that originate from the consumption of purchased energy (e.g., electricity or steam from a power plant). Scope 3 emissions are indirect emissions, or those that come from assets in a company’s supply chain that the company does not directly own, such as emissions from a contract manufacturer or for-hire truck carrier.

Existing Approaches to Measuring Trucking Emissions

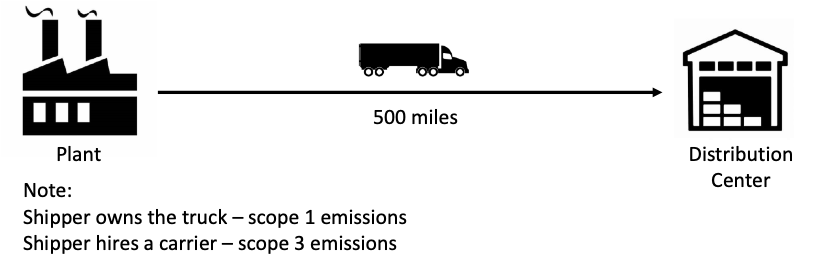

Let’s start with a simple example. Suppose a shipper needs to send a truckload of paper product 500 miles from a plant in Georgia to a distribution center in Indianapolis. If the shipper owns the truck, then the emissions from the truck would be scope 1. If the shipper uses a for-hire carrier, then these would be scope 3 emissions.

How should these emissions be measured? The Greenhouse Gas Protocol, an organization devoted to standardizing and measuring greenhouse gas emissions, suggests two general approaches (see Corporate Value Chain (Scope 3) Accounting and Reporting Standard, page 72):

- Direct measurement: measuring the emissions directly at the source using monitoring technology.

- Calculation: estimating the emissions using activity data (e.g., miles traveled) and an emissions factor.

Direct measurement may work well for large, fixed assets such as power plants, but it is not feasible for truck transportation. Tailpipe monitoring technology exists, but it is not widely used and would be expensive to implement. A direct measurement standard for trucking would require that these devices be manufactured, maintained, and disposed of in the millions. Data storage, maintenance, and sharing would be extremely difficult, as trucking is a famously fragmented industry with hundreds of thousands of small companies and millions of trucks. Moreover, the marginal value of these data compared to sound calculation is small. In other words, for trucking, the costs of directly measuring carbon emissions outweigh the benefits, relative to an alternative approach.

Estimating carbon emissions using well-designed calculations is a better path. The historical method for estimating carbon emissions from trucking has been to use a single emissions factor and multiply that factor by miles to get carbon emissions. For example, the Environmental Protection Agency (EPA) currently recommends a factor of 1.387 kg CO2 per mile for truckload moves, which is roughly equivalent to the emissions from a model year 2021 truck.

While a single emissions factor is better than nothing, this approach is simplistic and suffers from three major deficiencies:

- EPA’s recommended factor (1.387 kg CO2 per mile) does not accurately represent the emissions profiles of the actual trucks on our roads. I have compiled and maintain a database of millions of trucks and hundreds of thousands of carriers. The average tractor-trailer on the road has an emissions rate of around 1.617 kg CO2 per mile, an increase of 16.6% over the single metric. Even more discomforting, about 32% of the trucks on the road have an emissions rate at or above 1.760 kg CO2 per mile, and around 10% have an emissions rate at or above 1.857 kg CO2 per mile. These trucks have actual emissions that are 25-34% higher than the recommended rate.

- Using a single factor diverges from longstanding federal policy requiring truck manufacturers to produce cleaner trucks over time. Lower emissions are required by law; why wouldn’t emissions calculations reflect this policy?

- A single factor also does not incentivize shippers to use relatively clean carriers in their supply chains or reward shippers that do so. Suppose a shipper is dedicated to minimizing their scope 3 emissions by only hiring carriers that use EPA-certified trucks. A single factor does not capture the shipper’s reduced footprint due to this sourcing strategy. In fact, a single factor would rate a shipper that uses carriers with the newest, cleanest trucks exactly the same as a shipper that uses carriers with the oldest, dirtiest trucks.

Estimation using a single emissions factor is certainly more cost-effective than prohibitively expensive direct measurement—but at a significant sacrifice of precision and accuracy. In short, existing approaches do not strike a desirable balance. We need a better approach.

In my next article, I will discuss a method to calculate transportation emissions efficiently and accurately with an emphasis on the truckload industry. However, these principles can be applied to other types of truck movements (LTL, last-mile, parcel) with minor adjustments. While I focus on carbon emissions, the same method can be applied to the other major pollutants from trucks, such as particulate matter and NOx.