Transportation is among the largest sources of greenhouse gas emissions. In 2023, the U.S. government released a plan to “eliminate nearly all greenhouse gas emissions from the [transportation] sector by 2050.”1 While the rail industry is one of the more carbon-efficient modes of transportation, it has, nonetheless, been the target of environmental regulations urging the industry towards “zero-emission” technologies.

In this article, I will analyze emissions in the rail industry and evaluate potential policies to encourage rail decarbonization. First, I quantify the total emissions based on industry fuel consumption. Then, I estimate the cost of those emissions based on guidance from the U.S. Department of Transportation (DOT). Finally, I assess how realistic and cost-effective it might be for policy to require rail operators to adopt zero-emission2 locomotives in their operations.

I take a cost-benefit perspective, where a policy must be justified based on the value of reduced or avoided emissions. Due to the availability of data, I focus on Class I railroads and ignore emissions displacement, meaning those associated with electricity generation (or some other fuel source, such as hydrogen). Lastly, I do not hone in on a particular zero-emission technology but assume that rail operators will decide the best option.

Benefits of zero-emission locomotives

The primary benefit of moving from diesel-electric locomotives to a zero-emission alternative is the reduction of carbon dioxide (CO2) and criteria pollutant emissions through reduced diesel fuel consumption. The United States Environmental Protection Agency (EPA) regulates emissions from locomotives based on the tier of the locomotive, where higher-tier locomotives are required to meet more restrictive emissions standards.

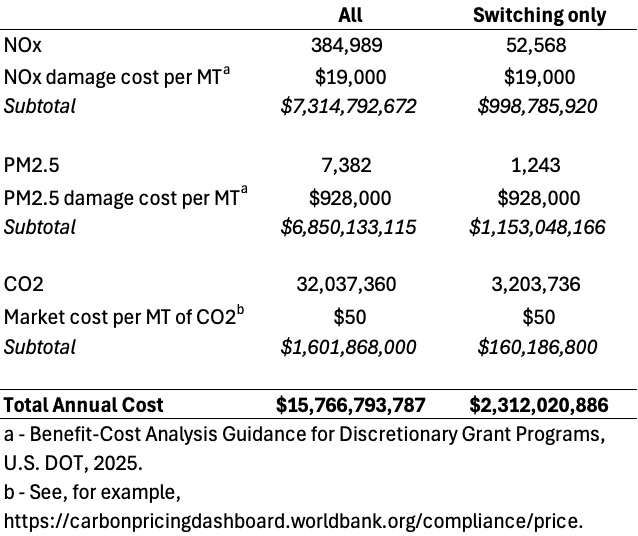

The main criteria pollutants emitted by diesel-electric locomotives and regulated by the U.S. Department of Transportation (DOT) are nitric oxide and nitrogen dioxide (generally referred to as NOx) and particulate matter (PM2.5). The DOT estimates the cost of a metric ton (MT) of NOx at $19,000 and PM2.5 at $928,000 in 2025.3 While current guidance from the DOT suggests that cost-benefit analyses should not include a monetary value for CO2 reductions, I will use a value of $50 per MT reduction in CO2, consistent with prior studies4 and current carbon prices.5

The Association of American Railroads (AAR) reported that Class I railroads burned 3.144 billion gallons of diesel fuel in 2022.6 Fuel is burned through two modes of operation: linehaul moves, where a locomotive moves from one location to another (e.g., Los Angeles to Chicago), and switching operations, where a switcher locomotive moves cars around a rail yard. Switching operations account for roughly 10% of the total fuel consumed by Class I railroads (314.4 million gallons of diesel).7

How much pollution is avoided?

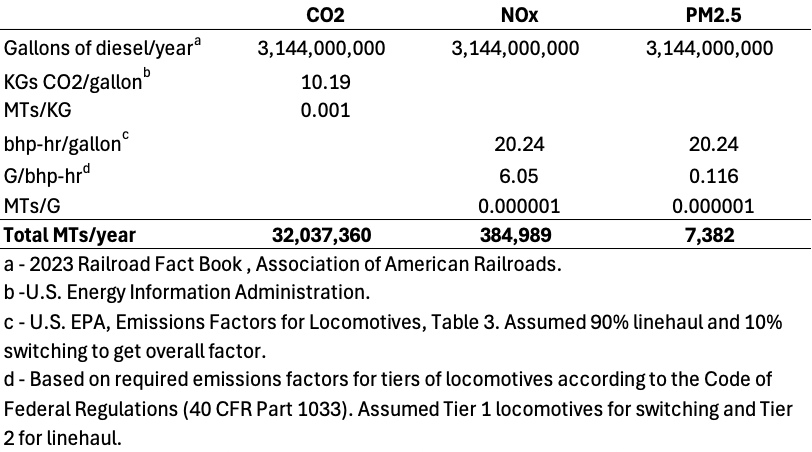

The cost of pollution is typically measured as a cost per metric ton, so gallons of diesel must be converted to metric tons for CO2, NOx, and PM2.5. For CO2, the calculation is straightforward: each gallon of diesel emits around 10.19 kilograms of CO2,8 meaning that Class I railroads emitted around 32 million MTs of CO2 in 2022 (see Table 1).

For NOx and PM2.5, the calculation is more complicated.

Emissions rates for NOx and PM2.5 are regulated by the tier of locomotive,9 with the most recent being Tier 4 (i.e., locomotives manufactured in 2015 or later). NOx and PM2.5 emissions are measured in grams per brake horsepower-hour (g/bhp-hr). Thus, gallons of diesel must first be converted to brake horsepower-hours, which can then be converted to grams and MTs of the pollutant.

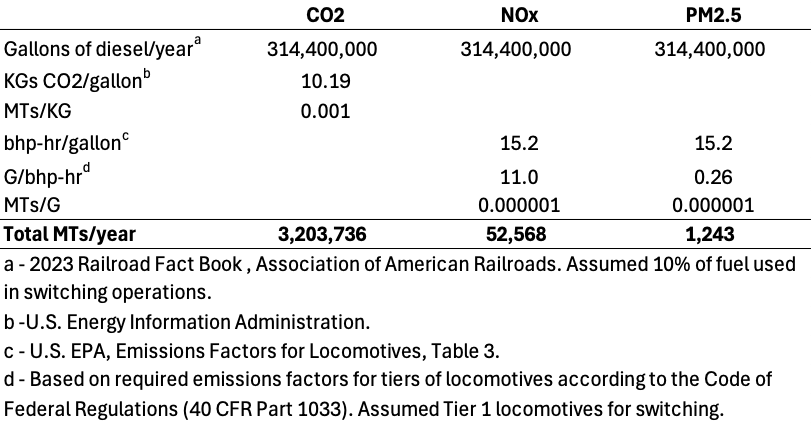

The EPA reports conversion factors for brake horsepower-hour per gallon (bhp-hr/gal), where 20.8 bhp-hr/gal is used in linehaul operations and 15.2 bhp-hr/gal is used in switching operations.10 To get an overall conversion factor, I weighted the linehaul and switching factors by 90% and 10%, respectively, to get 20.24 bhp-hr/gal. Using g/bhp-hr emissions factors from the Code of Federal Regulations and assuming Tier 2 linehaul locomotives and Tier 1 switcher locomotives gives weighted emissions factors of 6.05 g/bhp-hr NOx and 0.116 g/bhp-hr PM2.5.11 Multiplying the gallons consumed by the brake horsepower-hour per gallon and the grams per brake horsepower-hour factors and converting to metric tons gives an overall estimate of 384,989 MTs of NOx and 7,382 MTs of PM2.5 emitted from rail operations annually. Table 2 shows similar calculations for switching operations only.

Valuing rail pollution

The DOT estimates the cost of a metric ton of NOx to be $19,000. A metric ton of PM2.5 is $928,000. While the DOT suggests that researchers not consider the cost of carbon dioxide emissions in grant proposals, I assume a cost of $50 per MT CO2, which aligns with the value in carbon offset markets. Using these values, the annual cost of pollution for all Class I rail operations is $15.8 billion, and the cost of pollution for switching operations is $2.3 billion, as shown in Table 3.

Examining Full Electrification and Switching Options

The most viable path for a complete zero-emission rail network is catenary electrification, whereby overhead electrical lines power locomotives. Catenary electrification would most likely be an all-or-nothing transition, costing between $870 billion and $1.1 trillion to implement over decades.12 With an annual pollution cost avoidance of $15.8 billion, fully electrifying the rail network would have a payback period of 55 to 63 years, assuming a zero-discount rate and no inflation.

Such a long and uncertain payback period would not be an efficient use of capital for reducing emissions. There are many more cost-effective ways of removing or avoiding the emission of CO2 and other pollutants from the atmosphere.

Transitioning switcher locomotives to zero emissions is a more promising option. As shown in Tables 2 and 3, substantial pollution costs can be avoided by focusing on switching operations only as opposed to the whole rail network. The cost of pollution from switching is around $2.3 billion per year—a good business case for Class I rail operators to invest in and deploy zero-emission switcher engines.

Another advantage of such an approach is that switcher locomotives could be converted to zero-emission technologies piecemeal, as opposed to all at once, allowing railroads to invest in cleaner locomotives over time. Switcher locomotives can operate independently of linehaul operations, minimizing potential disruptions from the transition. Switching yards are typically around population centers, where NOx and PM2.5 emissions are most impactful. Thus, the value of reducing these more local pollutants is higher for switcher locomotives than for linehaul locomotives.

An immediate transition of all switching locomotives would not be viable or cost-effective. There are 4,854 switcher locomotives used by Class I railroads, and battery-electric switcher locomotives are relatively new and currently being tested. Assuming a cost of $5 million per locomotive,13 this would cost around $24 billion.14 Moreover, manufacturing capacity to make them would take years to ramp up, and proving their effectiveness in the field would require years of learning and adapting. However, the cost of pollution from switcher locomotives justifies a substantial annual investment from Class I railroads into cleaner alternatives.

Conclusions

The rail industry is among the cleanest modes of ground transportation, moving massive amounts of freight efficiently from an environmental point of view. Nonetheless, if we are to transition to a low- or zero-carbon economy, it must find ways to remove CO2 and other pollutants from its operations.

Most pollution (CO2 and criteria pollutant emissions) comes from two sources of operations: linehaul and switching. While linehaul operations account for the most pollution, transitioning to low- or zero-emission would be far more costly and complex than transitioning switching operations. While there is no current business case for transitioning linehaul operations, there is a strong case for Class I railroads to invest in and transition switcher locomotives to zero-emission alternatives over time.

What might a federal policy look like to encourage the rail industry to reduce emissions?

It is helpful first to rule out alternatives that have been considered. California recently attempted to require zero-emission locomotives for all rail operations within the state. This arbitrary policy would be extremely costly and could increase emissions because it would make rail unattractive on the entire western half of the country. Second, full electrification would not be cost-justified by emissions reductions. In lieu of this approach, policymakers would be better off finding other ways of reducing emissions with the roughly $1 trillion such a policy would cost.

However, policies targeting switching operations could be sensible and effective. One viable policy would mandate that a percentage of switching operations be performed by zero-emission locomotives after the technology has been proven and the manufacturing capacity put in place. For example, 5% of switcher locomotives could be required to be zero-emission by 2040, 10% by 2045, and so on. This approach would give the Class I railroads flexibility to determine the technology to implement, time to test out the technologies in their operations, and methodically phase out older switcher locomotives.

Alex Scott is an associate professor of supply chain management and the Gerald T. Niedert Professor in the Haslam College of Business at the University of Tennessee, Knoxville and a founding member of GSCI’s Transportation and Logistics Collaborative. He has spent the last two decades researching and working in the transportation industry. If you have inquiries about his research, contact him at ascott79@utk.edu.

- The U.S. National Blueprint for Transportation Decarbonization, U.S. Department of Energy, Department of Transportation, Environmental Protection Agency, and Department of Housing and Urban Development https://www.energy.gov/sites/default/files/2023-01/the-us-national-blueprint-for-transportation-decarbonization.pdf. ↩︎

- Of course, power generation (such as generating electricity) does not have zero emissions. For simplicity, I exclude these emissions, but they would be non-trivial. Thus, all of my estimates can be considered best-case. ↩︎

- Benefit-Cost Analysis Guidance for Discretionary Grant Programs, Office of the Secretary of the U.S. Department of Transportation, May 2025 https://www.transportation.gov/sites/dot.gov/files/2025-05/Benefit%20Cost%20Analysis%20Guidance%202025%20Update%20II%20%28Final%29.pdf. ↩︎

- Study of Catenary Electrification of the North American Class I Railroad Network, Association of American Railroads, December 2024 https://www.aar.org/wp-content/uploads/2025/02/Final-Electrification-Report-02252025.pdf. ↩︎

- See, for example, https://carbonpricingdashboard.worldbank.org/compliance/price [accessed May 19th, 2025]. ↩︎

- 2023 Railroad Fact Book, Association of American Railroads. The amount of fuel burned each year is pretty stable; for example, the same amount was burned in 1985. ↩︎

- Association of American Railroads. Consistent with this estimate, the U.S. Environmental Protection Agency reported that switching operations account for roughly 7% of fuel consumption, including passenger rail and non-Class I railroads. See Table 4 in “Emissions Factors for Locomotives,” U.S. EPA, April 2009 https://nepis.epa.gov/Exe/ZyPDF.cgi?Dockey=P100500B.pdf. ↩︎

- U.S. Energy Information Administration, https://www.eia.gov/environment/emissions/co2_vol_mass.php. ↩︎

- See the Code of Federal Regulation, 40 CFR Part 1033, https://www.ecfr.gov/current/title-40/chapter-I/subchapter-U/part-1033. ↩︎

- U.S. EPA, Emissions Factors for Locomotives, Table 3. https://nepis.epa.gov/Exe/ZyPDF.cgi?Dockey=P100500B.pdf. ↩︎

- Tables 1 and 2 from the Code of Federal Regulation, 40 CFR Part 1033, https://www.ecfr.gov/current/title-40/chapter-I/subchapter-U/part-1033. ↩︎

- Study of Catenary Electrification of the North American Class I Railroad Network, Association of American Railroads, December 2024 https://www.aar.org/wp-content/uploads/2025/02/Final-Electrification-Report-02252025.pdf. ↩︎

- Ibid. ↩︎

- This assumes a one-for-one replacement of diesel-electric switcher locomotives with zero-emission switcher locomotives. This is unlikely; the actual need could be as high as two for one due to the need to, for example, recharge batteries on electric locomotives. ↩︎