This post is the third in the series, Raw Materials and Natural Resources in the Supply Chain, which explores the understudied, and often misunderstood, processes for sourcing natural resources that are used as raw materials by the industries that make the products we buy every day. Read the first post about the dilemma farmers face in how to use their land. The second post explored the challenge of reshoring raw materials supply.

Just as the industries we’ve examined in the previous two blog posts, high technology is facing a sourcing challenge. I read an article recently from the Montana Standard that examined new methods scientists are using to source rare earth metals from a closed copper mine. In that mine is a lake. But it’s not the kind that you normally think of when you hear that word—it is made up of toxic wastewater from generations of mining.

The article tells the story of how we may innovate to source critical metals in a more environmentally sound manner. But, as I read it, I also reflected on two important aspects for understanding the extraction of metals used by modern industries: heterogeneity and economics.

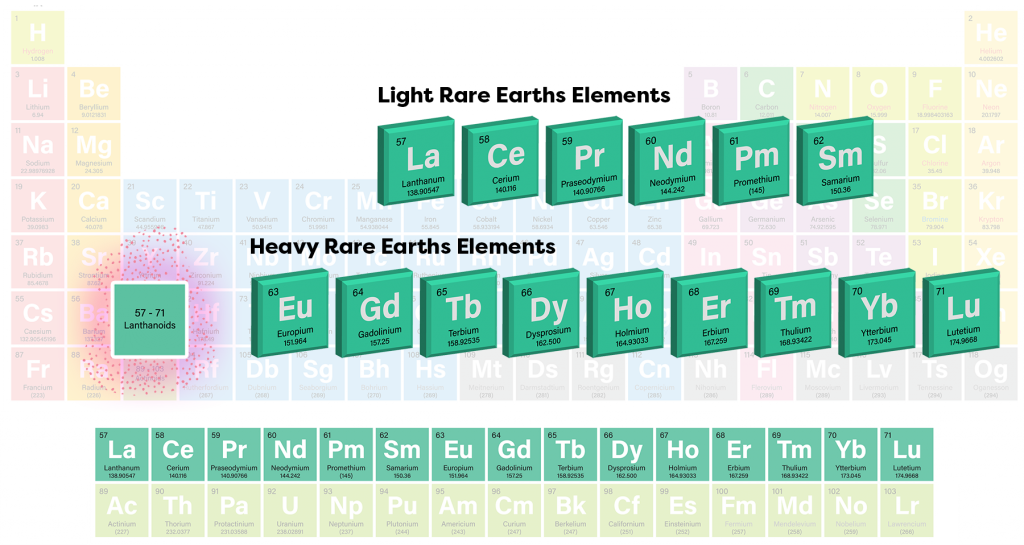

Rare earth elements (REE) are a set of 17 very distinct heterogeneous metals that are not household names. These metals are critical for making batteries, magnets, wind turbines, computer components, and a host of other hi-tech products. Why do we lump these 17 elements into a single group? And does it create confusion in the supply chain and poor perception of the availability of each of these 17 metals by doing so? Previously, we discussed our limited understanding about the variety of specifications—heterogeneity—of even simple raw materials, such as sand. Rather than acknowledging the individual properties and management of these 17 individual metals, we tell our corporate leaders and customers about issues related to rare earths. This ambiguity becomes problematic quickly.

This group of metals is divided into two categories: heavy and light rare earths. The mining and processing of each is distinct and often carried out in different locations in the supply chain. Recent efforts at the La Paz mining project in Arizona focus on the light class of these metals; it will not provide all 17 of the rare-earth metals. In other words, if your firm is need of the other dozen metals, then you may be dependent on other sources, often based in China, for the mining and processing of these metals.

Supply chain managers responsible for such sourcing must look at the individual needs of their supply chain networks for each metal. It would make more sense to describe the supply chain of neodymium—used in magnets, electric cars, and cell phones—or the supply chain of yttrium—used in lasers, radars systems and for hardening metal alloys—than a supply chain that encompasses the whole group. Each metal has its relevant supply chain issues and risks.

Besides heterogeneity, the Standard article asks us to consider the history and economics of mining valuable metals around the world. For decades, economists have pointed out that humans always extract the highest quality and easiest to acquire natural resources first. For example, in the 1860s, in the area around Butte Montana—once called the richest hill on earth—gold nuggets (placer gold) were literally found scattered on the ground and creek beds. After gold mining slowed, Butte and its surrounding towns became the centerpiece of Montana’s Copper Kings and home of the Anaconda Company, once among the largest copper mining companies in the world. The geologic concentration of precious metal ores in this area of Montana led Silver Bow County to be mined for gold, silver, copper, and other precious metals for over 120 years. That transformed the richest hill on earth into the Berkley Pit, one of the deepest and largest open copper mines in the United States.

After its closure in the mid-1980s, the Berkeley Pit was left filled with toxic groundwater containing cyanide and other wastes from decades of mining activity. It has been discovered that this wastewater also contains a high concentration of rare-earth metals. Incredibly, Paul Ziemkiewicz and his colleagues from West Virginia University’s water research institute have innovated a new process to extract rare earth elements from the wastewater in the Berkley Pit. After 40 years of being closed, it is possible that the richest hill on earth will be mined one more time!

But this time it appears a closed-loop supply chain solution could simultaneously help with processing wastewater in the pit. It may actually be a step towards environmental cleanup and sustainability, essentially killing two birds with one stone: sourcing valuable metals and processing the toxic wastewater left over from decades of mining. Up to this point in the 21st century, the toxic waters of the Berkeley Pit have been most famous for killing geese. So this would be a welcome step for both environmentalists and miners alike.

The moral of this story is that human industry has driven the need for precious metals for centuries, and the scarcity and value of such metals has caused us to dig deeper into the earth to meet the needs of the planet’s 8 billion people. While our processes haven’t always been sustainable and respectful of our planet, science and technology today offer the ability to innovate new solutions for sourcing precious metals in a sustainable fashion.

In the hunt for heterogenous natural resources, such as neodymium and yttrium, we can continue to follow thousands of years of precedent for discovering valuable ores by digging deeper and deeper. Or we can employ other strategies, such as the closed-loop approach, taking the pressure off the environment and employing recycling and recovery approaches to reuse metals that have been disposed of into waste streams by industry. Supply chain managers and design engineers should consider each specific metal’s heterogeneous properties, availability, and costs and not assume that availability is ensured for any raw material by using a single supply chain strategy—especially not for a group of 17 metals with distinct supply and demand characteristics.

To ensure a sustainable future, innovation, technology, and insightful supply chain management must combine to achieve a balanced approach to ensuring the availability of raw materials, while still taking into account the unique and demanding requirements of the world we live in today.